Biocatalytic Oleochemical Processing

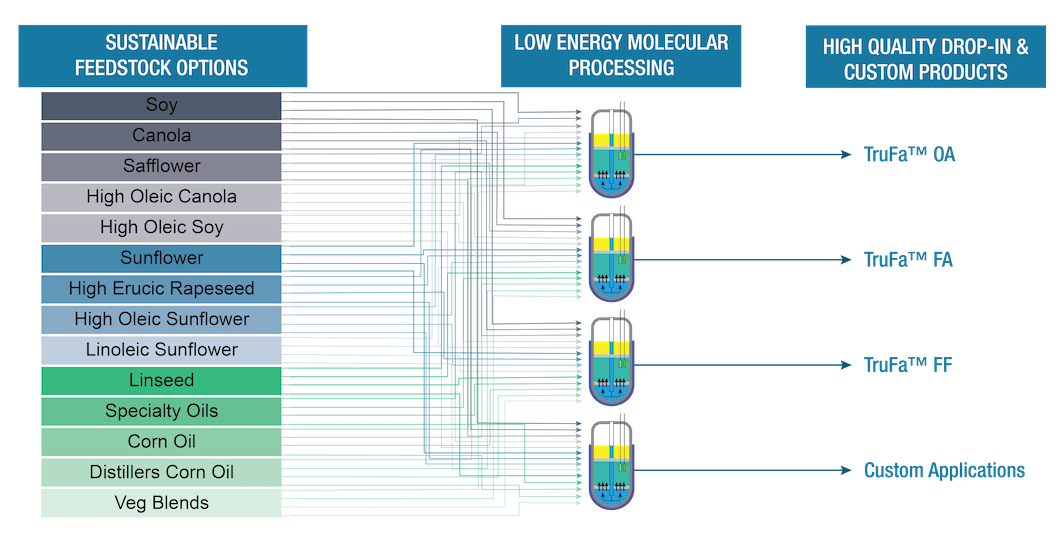

Our biocatalytic splitting technology (BST) advances the sustainability, reliability and quality of oleochemical production. With palm oil and tallow under sustainability and cost pressures, BST produces a variety of fatty acid products from more than a dozen domestically sourced vegetable- and seed-oil feedstocks. Even better, our modular processing technology allows us to support your application needs with custom products—even at small batch sizes.

Gentle, Efficient Oleochemical Processing

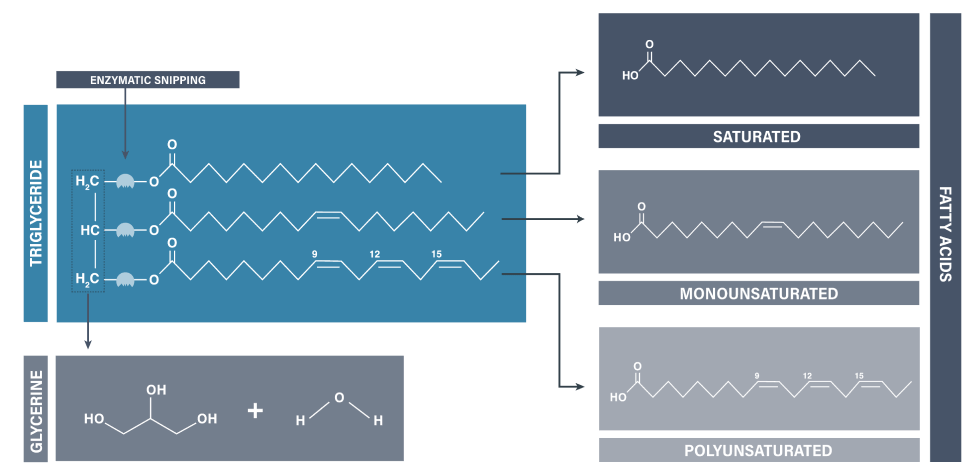

BST relies on a proprietary catalyst-enabled hydrolysis process to split and partition plant-based oils into their intermediate chemistries. Its bioreactor design enables efficient reactions, water conservation, high-yield fractionation and glycerin recovery. And unlike conventional oleochemical processes, the inherently low-energy BST process operates at ambient pressures and temperatures. The advantages to these gentle process conditions include:

- Protecting oleochemical feedstocks and end products from harmful thermal stresses

- Preventing unwanted side product reactions and waste—such as alkene production

- Reducing energy demands, carbon footprint, greenhouse gas emissions and volatile organic compounds (VOC)

Compared to conventional oleochemical processes, BST also requires fewer refining steps to achieve high yields and product purity, which contributes to its energy and greenhouse gas reduction.

Modular Process Supports Feedstock Agility

The BST system features a modular design to further boost production agility and adaptability. Our technology enables agile manufacturing, which allows for granular adjustments to the process based on feedstock characteristics, availability and the desired fatty acids. The technology can operate in batch or semi-continuous mode, and modular processing lines allow for quick and efficient transitions between feedstocks with minimal downtime. Our modular process allows us to support you in the development of small-batch custom products and applications.

Our Production Capabilities

Plant

- Located in northwest Ohio

- 190,000 sqft building on 30-acre site

Process

- Hydrolysis

- Sweetwater Evaporation

- Simple Fatty Acid Distillation

- Fractal Fatty Acid Distillation

Logistics

- Tote and Drum Packing (MTO)

- Finished Product Bulk Storage

- Rail infrastructure serviced by CF&E line via CSX

- Drive-through automated truck load and unload

Freely Blendable Feedstocks

Sustainable and Flexible Supply Chain

Beef tallow and palm oil have long been the incumbent feedstocks for the oleochemical industry. However, both the tallow and palm oil industries increasingly suffer from supply chain disruptions and unpredictable costs. The causes for this uncertainty are rooted in deforestation, climate change and societal pressures that are unlikely to diminish. Our vegetable-based feedstocks are reliably sourced from local sources and not subject to negative global forces affecting supplies of tallow and palm oil.

- Feedstock agility. Our technology enables the production of high-quality fatty acids from over a dozen different seed and vegetable oils. This feedstock agility lets us adjust our feedstock sources to meet market demands and avoid the supply challenges of beef tallow and palm oil. Additionally, vegetable production is a strong and long-established industry in the United States-and it’s always growing.

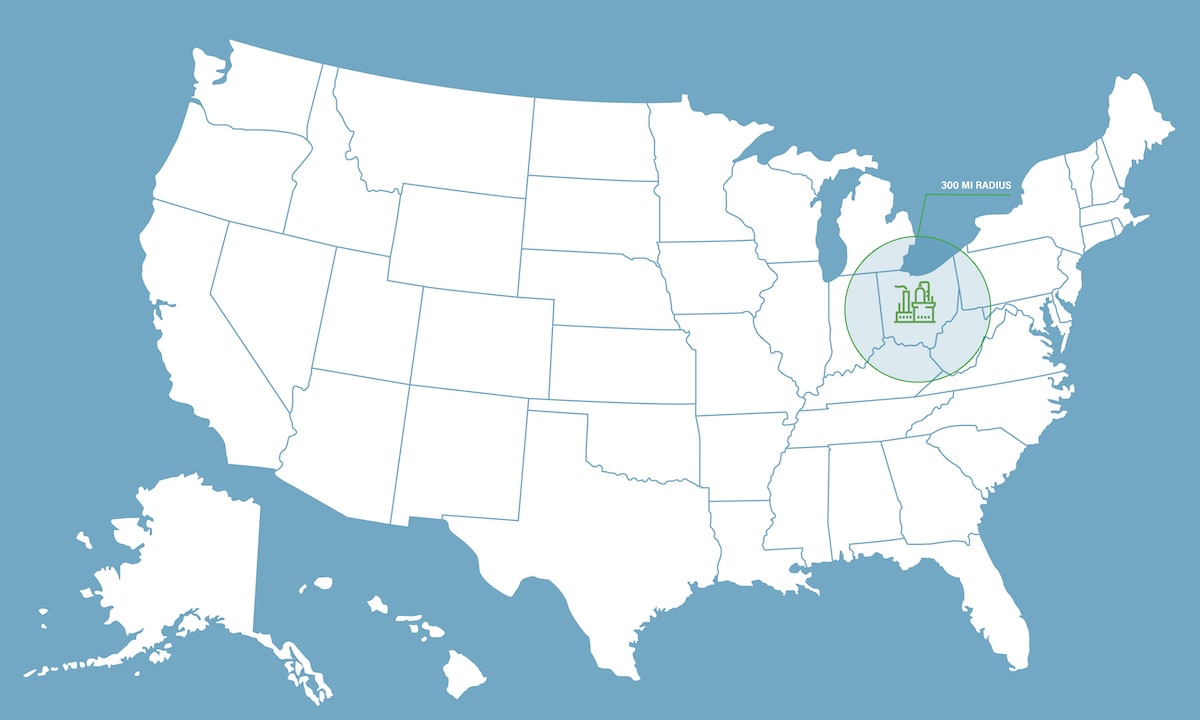

- Longstanding, local suppliers. We have a qualified, established purchasing history with over a dozen seed oil suppliers that range in scale and scope. By leveraging multiple feedstock sources, we avoid reliance on single-source supplies. In addition, a high-density area of supply, crushing and refining resources operate within a 300-mile radius of our facility. This advantageous position cuts down on our raw material and product transportation times and boosts the resiliency of our supply chain.

how can we help you?

Contact us today to get started.

7400 Newman Boulevard, Dexter, MI 48130

(734) 205-1611

©2026 Trucent Renewable Chemicals. All Rights Reserved.